Pickleball

Pickleball is a popular racquet sport that is enjoyed by millions of people all over the world. The game is played with a small, light ball that is designed to bounce and spin in a specific way. To ensure that pickleball balls are of the highest quality and perform optimally, it is important to understand the materials and manufacturing processes used to make them.

As the sport has gained popularity, so has the demand for high-quality pickleball equipment, including balls. In this article, we’ll explore how pickleball balls are made and the various factors that go into ensuring their quality and performance.

Pickleball Ball Characteristics & Specs

Pickleball ball diameter: 2.874 inches (73mm)

Weight: 0.9 – 1.0 ounces (26-28 grams)

Bounce: must bounce between 29 and 34 inches when dropped from a height of 78 inches

Material: usually made of plastic polymer with a hollow center

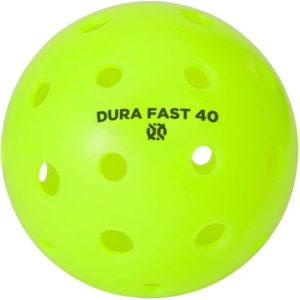

Color: typically bright yellow or green for high visibility

Regulation: balls must meet standards set by the USA Pickleball Association (USAPA)

The Importance of Pickleball Ball Quality

The quality of a pickleball ball can greatly impact the playing experience. Poorly made balls can result in unpredictable bounces, inconsistent flight patterns, and a lack of control for players. On the other hand, high-quality pickleball balls are designed to provide consistent performance, ensuring that players can accurately predict the trajectory of the ball and react accordingly. This can make the difference between an enjoyable game and a frustrating one.

Another important factor to consider when choosing a pickleball ball is the size and weight of the ball. Pickleball balls are typically between 2.7 and 2.9 inches in diameter and weigh between .8 and 1 ounces. The size and weight of the ball are regulated by the USA Pickleball Association to ensure that all balls used in competition are consistent.

Materials Used to Make Pickleball Balls

The most common material used to make pickleball balls is polymer, a type of plastic. Polymer is a popular choice for ball manufacturing because it is lightweight, durable, and can be molded into different shapes. Additionally, polymer balls can be made to be water-resistant, making them suitable for outdoor play.

What is Polymer Plastic?

Polymer plastic is a type of plastic material made by linking together monomers, which are small repeating units, to form a long chain. There are many different types of polymer plastics, each with unique properties and uses.

Some common examples of polymer plastics include:

Polyethylene (PE): used for products like shopping bags, toys, and packaging

Polypropylene (PP): used for products like car parts, medical devices, and packaging

Polyvinyl chloride (PVC): used for products like pipes, electrical cables, and clothing

Polystyrene (PS): used for products like foam packaging and disposable cutlery

Polymer plastics are popular in a wide range of products due to their durability, versatility, and cost-effectiveness. They can be molded into a variety of shapes and sizes and can be designed to have specific properties, such as heat resistance or transparency.

Manufacturing Process for Polymer Pickleball Balls

Making a high-quality pickleball ball requires a combination of precision, expertise, and state-of-the-art manufacturing processes. Whether you’re an experienced player or a beginner, understanding the process of how pickleball balls are made will help you choose the right ball for your needs and ensure that you have a great time on the court.

Step 1: Creating the Mold

The first step in the pickleball ball manufacturing process is to create the mold that will be used to form the ball. The mold is usually made from a combination of metal and plastic and is designed to fit the specific dimensions and performance characteristics of the ball. The mold is created using a computer-aided design (CAD) program, which ensures precise and accurate dimensions.

Step 2: Filling the Mold

Once the mold is complete, it is filled with the material that will be used to make the ball. This material can be plastic, polymer, or a combination of both. The mold is then placed into a heating and cooling chamber, where the material is melted and then cooled to solidify.

Step 3: Removing the Flash

The solidified ball is then removed from the mold and subjected to a process called flash removal. During this process, any excess material is trimmed away to ensure that the ball is the correct size and shape. This step is crucial to ensure that the ball meets industry standards and performs optimally on the court.

Step 4: Cross-Linking

For polymer balls, an additional step called cross-linking is performed. This process involves exposing the ball to high temperatures and pressures, which helps to strengthen and stabilize the material. Cross-linking ensures that the ball has consistent performance characteristics and a long lifespan.

Step 5: Testing and Quality Control

Regardless of the material used, the final step in the pickleball ball manufacturing process is to inspect and test the ball for quality. This process typically involves measuring the ball’s size, weight, and bounce characteristics to ensure that it meets industry standards.

If the ball passes all of the tests, it is packaged and shipped to retailers or directly to customers. If the ball does not meet quality standards, it is discarded and the manufacturing process begins again.

Choosing the Right Pickleball Balls

When choosing pickleball balls, there are several factors to consider, including the material used, the size and weight of the ball(indoor or outdoor), and the brand. It’s important to choose balls that are made from high-quality materials and are the correct size and weight to ensure consistent performance. Additionally, choosing a reputable brand can help ensure that the balls have been manufactured using proper procedures and standards.

Conclusion

In conclusion, the process of making a pickleball ball involves molding, cutting, and packaging high-quality polymer materials. By understanding how pickleball balls are made and the various factors that go into their quality, players can make informed decisions when choosing the right balls for their needs. Whether you’re a seasoned player or just starting out, choosing the right pickleball balls can greatly impact the enjoyment and success of your game.

This site is a participant in the Amazon Associates Program, an affiliate advertising program as a way to earn fees by linking to Amazon. We earn a small commission when a product is purchased on amazon that links from this page.